COLLEGE OF ENGINEERING & SCIENCE

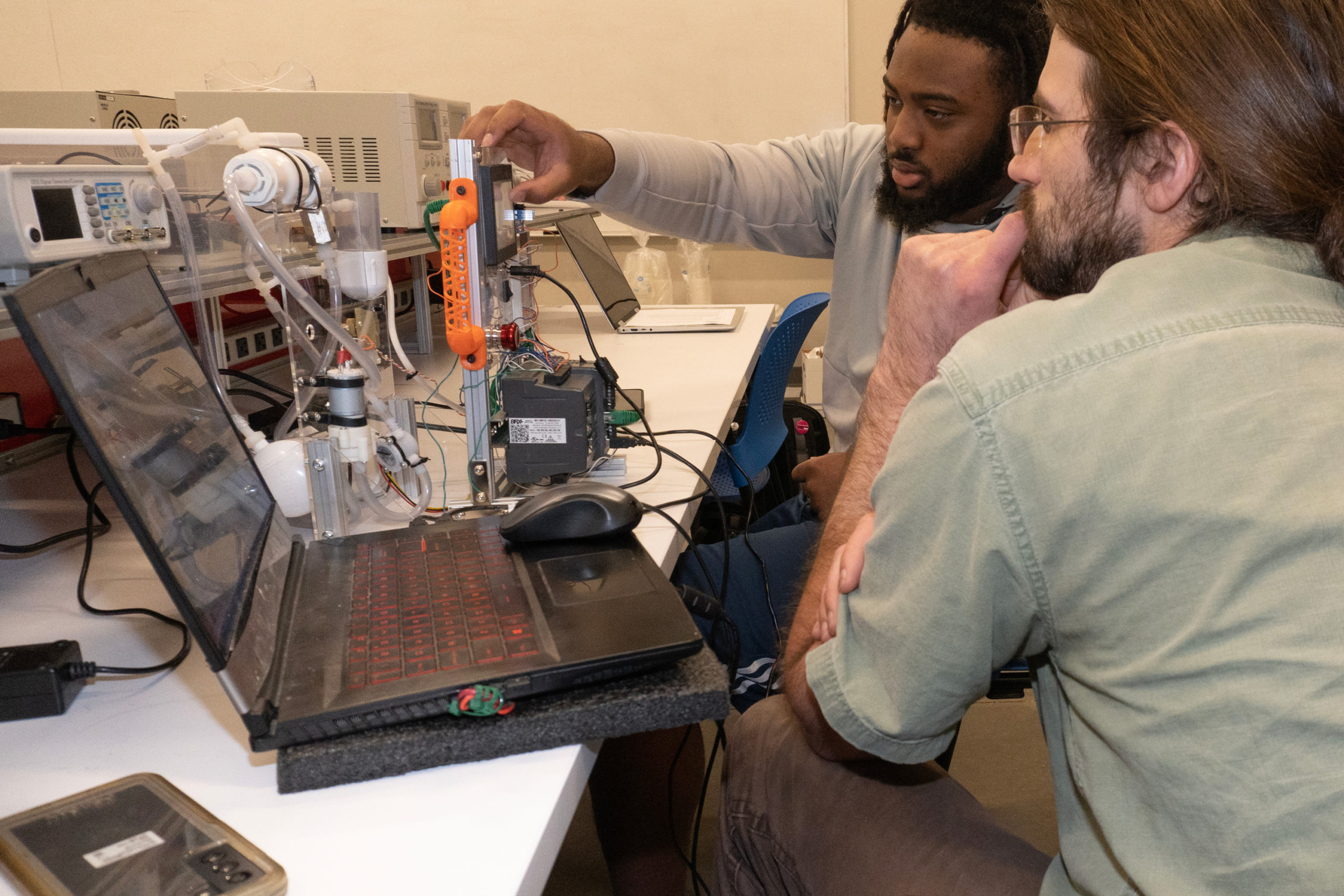

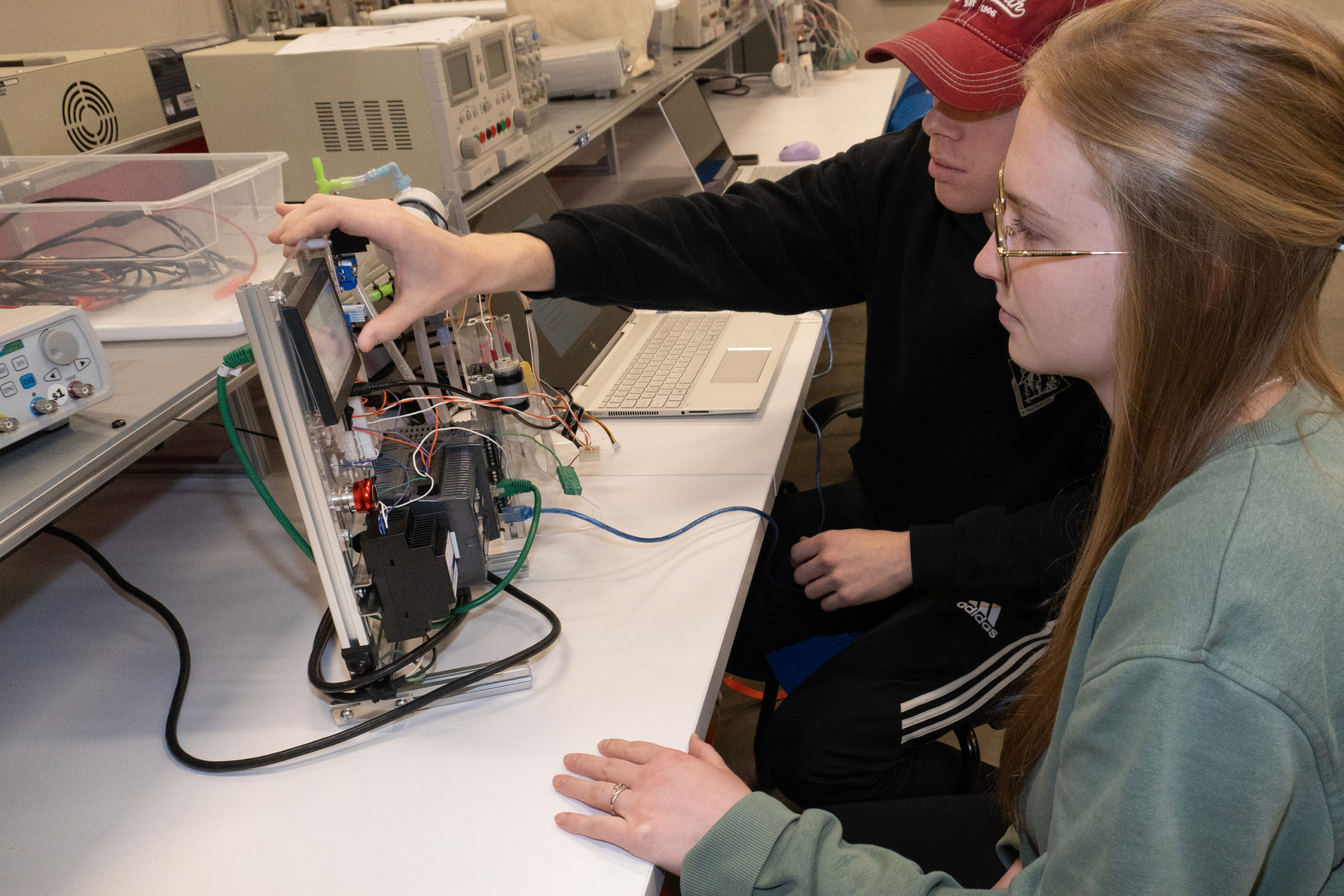

Instrumentation and Control Systems Engineering Technology

The Instrumentation and Control Systems Engineering Technology (ICET) program prepares students to meet the demands of our increasingly automated society, providing expertise in sensors and calibration, programmable logic controllers, process troubleshooting, robotics and electrical power. ICET graduates are familiar with instrumentation, discrete and analog control systems, microcontrollers, data collection and transfer and networking. They design, plan, research, evaluate, test and implement electrical and electromechanical systems that span the biomedical, chemical, civil, cyber, electrical, industrial, mechanical and nanosystems disciplines.

Interested in Joining Our Program?

Whether you’re interested in joining our program or just have questions, we’re here to help.

Program Highlights

%

Percent of Students with Full-Time Employment by Graduation

Average Salary of Graduating Students in $

Job Opportunities

Graduates of the ICET program may work on projects involving industrial equipment, computers, cell phones, navigation systems, wiring and lighting in buildings, and other types of electrical and electromechanical systems.

- Aerospace Engineer

- Broadcast Engineer

- Electrical/Electronics Engineer

- IT Consulting

- Network Engineer

- Nuclear Engineer

- Systems Analyst

- Management Consulting

- Project Management

- Technical Writing or Sales

Instrumentation and Control Systems Engineering Technology Curriculum Sheet 2023

Instrumentation and Control Systems Engineering Technology Curriculum Sheet 2022

Instrumentation and Control Systems Engineering Technology Curriculum Sheet through 2021

Faculty

Assistant Professor

Departments: Electrical Engineering, Instrumentation and Control Systems Engineering Technology

Associate Dean of Undergraduate Studies, Academic Director of Instrumentation and Control Systems Engineering Technology and Industrial Engineering, Associate Professor of Biomedical Engineering

Departments: Biomedical Engineering, Center for Biomedical Engineering and Rehabilitation Sciences, Industrial Engineering, Instrumentation and Control Systems Engineering Technology, Molecular Science and Nanotechnology

Assistant Professor – Mechanical Engineering, First-Year Engineering Programs Coordinator, Director of the Office for Women in Science and Engineering

Departments: Instrumentation and Control Systems Engineering Technology, Mechanical Engineering

Professional-In-Residence

Department: Instrumentation and Control Systems Engineering Technology

Project-Based Learning Professional

Department: Instrumentation and Control Systems Engineering Technology

Senior Lecturer, Mechanical Engineering | Program Chair, Instrumentation and Control Systems Engineering Technology | Director, Project-Based Learning

Departments: Instrumentation and Control Systems Engineering Technology, Mechanical Engineering

Visiting Lecturer

Departments: Industrial Engineering, Instrumentation and Control Systems Engineering Technology

Project Based Learning Specialist

Departments: Engineering and Technology Management, Industrial Engineering, Instrumentation and Control Systems Engineering Technology

Professional in Residence

Department: Instrumentation and Control Systems Engineering Technology

Department: Instrumentation and Control Systems Engineering Technology